I-Granite iyitshe lemvelo elakhiwe ngokupholisa nokuqiniswa kwe-volcanic magma noma udaka lwentaba-mlilo.Kuwumsebenzi ominyene kakhulu futhi oqinile futhi amelana kakhulu nokuklwebheka, amabala, nokushisa.I-Granite isetshenziswa kakhulu embonini yezokwakha ezintweni zokwakha njengama-countertops, i-flooring, nama-facade ngenxa yamandla ayo kanye nokuqina.Ngokungeziwe kulezi zinhlelo zokusebenza, i-granite iphinde yathola indlela yayo embonini yedivayisi yokuhlanganisa ukunemba, lapho isetshenziswa kakhulu njengento eyisisekelo.

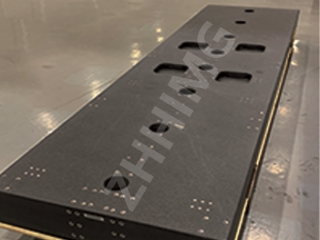

Amadivayisi wokuhlanganisa ngokunemba asetshenziswa ezimbonini ezihlukahlukene njengezezimoto, i-aerospace, nezokwelapha, lapho izindinganiso eziqondile zokunemba nokwethembeka kubalulekile.Kudingeka izinto eziyisisekelo kulawa madivayisi angahlinzeka ngokudambisa ukudlidliza okuhle kakhulu, ukuqina okuphezulu, nokuzinza kwe-thermal.I-Granite ihlangabezana nazo zonke lezi zidingo, okuyenza ibe inketho ekahle yesisekelo samadivayisi wokuhlanganisa anemba.

Enye yezinhlelo eziyinhloko ze-granite ezisetshenziswa ekuhlanganiseni ukunemba kusekukhiqizweni kwemishini yokulinganisa edidiyelwe (ama-CMM).Ama-CMM asetshenziswa ekukhiqizeni izitshalo ukukala ubukhulu bezingxenye ngezinga eliphezulu lokunemba.Le mishini isebenzisa isisekelo se-granite ngoba inikeza inkundla ezinzile nethembekile yesistimu yokulinganisa.I-Granite ine-coefficient ephansi kakhulu yokunwetshwa okushisayo, okusho ukuthi imelana kakhulu nezinga lokushisa.Lokhu kuyenza ibe impahla ekahle yokugcina ukunemba kwesistimu yokulinganisa.

I-Granite iphinde isetshenziswe kabanzi ekukhiqizeni amasistimu okuqondanisa optical.Lezi zinhlelo zisetshenziselwa ukuqondisa izingxenye ze-optical ezingeni eliphezulu kakhulu lokunemba.Isisekelo se-granite sibalulekile kulezi zinhlelo ngoba sinikeza izinga eliphezulu lokuqina, okudingekayo ukuze kugcinwe ukuqondanisa kwezingxenye ze-optical.I-Granite futhi imelana kakhulu nokudlidliza, okuyenza ifaneleke ukusetshenziswa ezindaweni lapho amazinga okudlidliza ephezulu, njengezitshalo zokukhiqiza.

Okunye ukusetshenziswa kwe-granite kumishini yokuhlanganisa enembile isekukhiqizweni kwemishini yokukhiqiza i-semiconductor.Ukukhiqizwa kwe-semiconductor kudinga izinga eliphezulu lokunemba ukuze kuqinisekiswe ukuthi izingxenye zenziwa ngendlela esezingeni elifanele.Isisekelo se-granite sinikeza ukuzinza nokuqina okudingekayo emishinini yokukhiqiza, okusiza ukuqinisekisa ukuthi izingxenye zenziwa ngendlela edingekayo.

Ngaphezu kwalezi zicelo, i-granite iphinde isetshenziswe ekukhiqizeni imishini yaselabhorethri, njengezilinganiso zokukala kanye nemishini ye-spectroscopy.Lawa madivayisi adinga izinga eliphezulu lokuzinza ukuze kuqinisekiswe izilinganiso ezinembile.Isisekelo se-granite sinikeza ukuzinza nokuqina okudingekayo kulezi zinhlobo zamadivayisi, okwenza kube ukukhetha okuhle.

Sengiphetha, i-granite iyinto eguquguqukayo kakhulu ethole ukusetshenziswa okubanzi embonini yobunjiniyela bokunemba.Izici zayo zokuqina okuphezulu, ukuncibilika kokudlidliza, nokuzinza kokushisa kuyenza ibe inketho efanelekile yezinto eziyisisekelo zamadivayisi wokuhlanganisa ngokunemba.Kusukela kuma-CMM kuya emishinini yokukhiqiza ye-semiconductor, i-granite ithole indlela yayo ezinhlobonhlobo zezinhlelo zokusebenza, isiza ukuqinisekisa ukuthi amadivaysi akhiqizwe kuya kumazinga aqinile okunemba nokuthembeka.Njengoba isidingo sezingxenye ezinemba kakhudlwana siqhubeka sikhula, kungenzeka ukuthi ukusetshenziswa kwegwadle kubunjiniyela bokunemba kuzoqhubeka nokukhula.

Isikhathi sokuthumela: Nov-21-2023