I-Granite iwuhlobo lwetshe lemvelo elisetshenziswa kabanzi ekusetshenzisweni okuhlukahlukene ngenxa yezici zayo eziyingqayizivele kanye nezakhiwo.Ukuqina kwayo, ukumelana nokuguga, nokumelana namakhemikhali kuyenza ibe yinto ekahle yokukhiqiza imishini enembayo ephezulu.Okunye okunjalo kwegwadle okwemikhiqizo yedivayisi yokuhlola iphaneli ye-LCD.Kulesi sihloko, sizoxoxa ngezindawo ezihlukahlukene zohlelo lokusebenza lwe-granite esekelwe kumadivayisi okuhlola amaphaneli e-LCD.

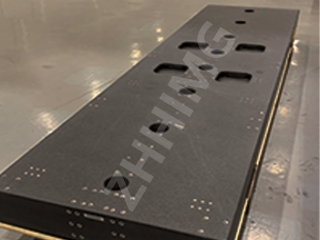

Imishini yokuhlola iphaneli ye-LCD isetshenziselwa ukuhlola ikhwalithi nokuvumelana kwezikrini ze-LCD ezisetshenziswa emishinini eyahlukene kagesi.Lawa madivayisi asetshenziswa enqubweni yokukhiqiza ukuze kuqinisekiswe ukuthi isikrini ngasinye sihlangabezana namazinga athile kanye nokucaciswa.Amadivayisi aqukethe izingxenye ezahlukahlukene ezisebenza ndawonye ukuze zihlole izikrini ze-LCD.Enye yezingxenye ezibaluleke kakhulu kulawa madivaysi yisisekelo, esenziwe nge-granite.

Ukusetshenziswa kwe-granite njengento eyisisekelo yamadivayisi okuhlola amaphaneli e-LCD kunezinzuzo ezimbalwa.Okokuqala, i-granite iyinto ezinzile kakhulu engakhuli noma ingafinyeleli ngenxa yokushintsha kwezinga lokushisa noma umswakama.Lokhu kuyenza ibe into efanelekile yezinto zokusebenza ezinemba kakhulu, njengoba iqinisekisa ukuthi idivayisi igcina ukunemba nokunemba kwayo ngokuhamba kwesikhathi.Okwesibili, i-granite iyinto enzima kakhulu ephikisana nokuguga, okusho ukuthi isisekelo sedivayisi sizohlala isikhathi eside ngaphandle kokudinga ukushintshwa.Okokugcina, i-granite iwumsebenzi ongewona uzibuthe, okusho ukuthi ngeke iphazamise noma yimaphi amasiginali kagesi noma kazibuthe phakathi nenqubo yokukhiqiza.

Enye yezindawo ezisetshenziswa kakhulu zemishini yokuhlola iphaneli ye-LCD ye-granite isekwekwenziweni kwezinto zikagesi ezifana nama-smartphone namathebulethi.Lawa madivayisi adinga izikrini ze-LCD zekhwalithi ephezulu ezingaguquki futhi ezithembekile.Ukusetshenziswa kwamadivayisi okuhlola asuselwa ku-granite kuqinisekisa ukuthi isikrini ngasinye sihlangabezana namazinga adingekayo kanye nokucaciswa, okusiza ukuthuthukisa ikhwalithi iyonke yomkhiqizo.

Enye indawo esetshenziswayo yamadivaysi okuhlola amaphaneli e-LCD asekelwe kugwadule ekwakhiweni kwemishini yezokwelapha njengemishini ye-X-ray nezikena ze-ultrasound.Lawa madivayisi adinga izikrini ze-LCD ezinemba okuphezulu okufanele zihlolwe futhi zihlolwe ukunemba nokuvumelana.Ukusetshenziswa kwamadivayisi okuhlola asuselwa kugwadle kuqinisekisa ukuthi isikrini ngasinye sihlangabezana nezicaciso ezidingekayo, okusiza ukuthuthukisa ukunemba nokuthembeka kwedivayisi yezokwelapha.

Ngaphezu kwemboni yokukhiqiza, amadivaysi okuhlola amaphaneli e-LCD asuselwa kugranite nawo ayasetshenziswa kumalebhu ocwaningo nokuthuthukiswa.Lawa madivaysi asetshenziselwa ukuhlola izikrini ezintsha ze-LCD nobuchwepheshe ukuze kuqinisekiswe ukuthi ahlangabezana namazinga adingekayo kanye nokucaciswa kwawo.Ukusetshenziswa kwamadivayisi okuhlola asekelwe ku-granite kuqinisekisa ukuthi imiphumela yalezi zivivinyo inembile futhi ithembekile, okusiza ukuthuthukisa ikhwalithi yemikhiqizo yesikhathi esizayo.

Sengiphetha, amadivaysi okuhlola amaphaneli e-LCD asuselwa kugranite anezindawo eziningi zohlelo ezimbonini ezahlukahlukene.Ukusetshenziswa kwe-granite njengento eyisisekelo yalezi zisetshenziswa kuqinisekisa ukuthi zinembile, zithembekile, futhi zihlala isikhathi eside, okusiza ukuthuthukisa ikhwalithi iyonke yemikhiqizo ekhiqizwa kusetshenziswa la madivayisi.Kungakhathaliseki ukuthi kusekwenziweni kwemishini kagesi, okokusebenza kwezokwelapha, noma ocwaningweni nasekuthuthukisweni, amadivayisi okuhlola asuselwa kugwadle adlala indima ebalulekile ekuqinisekiseni ukuthi izikrini ze-LCD zihlangabezana namazinga adingekayo kanye nokucaciswa.

Isikhathi sokuthumela: Nov-01-2023