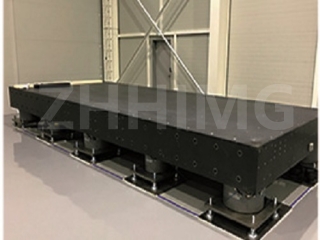

Uma kukhulunywa ngokukhiqiza imikhiqizo yokucubungula i-wafer, isisekelo somshini sibaluleke njenganoma iyiphi enye ingxenye.Isisekelo esiqinile, esizinzile sibalulekile ukuze kuqinisekiswe ukunemba kwenqubo yokwenza imishini kanye nokuvimbela noma yimuphi umonakalo ezingxenyeni ezibucayi.Nakuba insimbi iyisinqumo esivamile ezisekelweni zomshini, i-granite iyindlela ethandwa kakhulu ngenxa yezakhiwo zayo eziyingqayizivele.Nazi ezinye zezizathu zokuthi kungani i-granite ingase ibe ukukhetha okungcono kunensimbi yesisekelo somshini we-granite.

1. Ukuzinza nokuqina

I-Granite inokuminyana nokuqina okuphezulu kakhulu kunezinsimbi eziningi, okusho ukuthi inokumelana kangcono nokudlidliza nokunyakaza.Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza ze-wafer machining, lapho nokudlidliza okuncane noma ukunyakaza kungabangela ukungalungi noma ukonakala emikhiqizweni eqediwe.Ukuzinza nokuqina kwe-granite kuyenza ibe yinto efanelekile yezisekelo zomshini ezidinga ukunemba okukhulu.

2. Ukumelana nokushintsha kwezinga lokushisa

Enye yezinzuzo eziyinhloko ze-granite phezu kwezinsimbi yikhono layo lokumelana nokushintsha kwezinga lokushisa nokuhlukahluka.Lokhu kubalulekile ekucutshungulweni kwe-wafer, lapho izinga lokushisa lingashintshashintsha kakhulu phakathi nenqubo yokukhiqiza.Ngokungafani nezinsimbi ezingakhula noma zivumelane ngokushintsha kwezinga lokushisa, i-granite igcina ukuma nobukhulu bayo, iqinisekisa ukusebenza okuthembekile nokungaguquguquki.

3. Ukuqina nokuphila isikhathi eside

I-Granite ingenye yezinto ezinzima kunazo zonke ezitholakalayo, okwenza ukuthi imelane ngokwedlulele ukuguga, ukudabuka, nokulimala.Lokhu kuyenza ibe into efanelekile yezisekelo zomshini ezidinga ukumelana nemithwalo esindayo noma ukusetshenziswa njalo.Ngisho nangemva kweminyaka yokusetshenziswa, isisekelo somshini we-granite sizogcina ukuzinza, ukuqina, nokunemba, sinikeze ukusebenza okungaguquki nokuthembekile ngokuhamba kwesikhathi.

4. Izakhiwo ezingezona kazibuthe

Ngokungafani nezinsimbi, i-granite ayiyona i-magnetic, ebalulekile ekucubunguleni izinhlelo zokusebenza ze-wafer lapho ukuphazamiseka kazibuthe kungabangela umonakalo omkhulu.Isisekelo somshini we-granite siqinisekisa ukuthi izinkambu kazibuthe azikho endaweni yomshini, okunciphisa ubungozi bokuphazamiseka futhi kuthuthukise ukunemba kwenqubo yokwenza imishini.

5. Kulula ukunakekela nokuhlanza

I-Granite kulula ukuyihlanza nokuyinakekela, okubalulekile ekucubunguleni izinhlelo zokusebenza ze-wafer lapho ukuhlanzeka kubalulekile.Ngokungafani nezinsimbi, i-granite ayigqwali, ayigqwali, noma yonakalisi, okusho ukuthi idinga ukulungiswa nokuhlanza okuncane.Ukuhlanza nokugcinwa njalo kuzoqinisekisa ukuthi umshini usebenza kahle, uhlinzeka ngokusebenza kwemishini okunembayo nokuthembekile esikhathini eside sokuphila.

Sengiphetha, nakuba izinsimbi bekuyinketho evamile ezisekelweni zemishini, igwadle liyindlela ethandwa kakhulu ngenxa yezakhiwo zayo ezihlukile.Ukukhetha isisekelo somshini we-granite ngaphezu kwensimbi kungaba nezinzuzo ezibalulekile, okuhlanganisa ukuzinza, ukuqina, ukumelana noshintsho lokushisa, ukuqina, izakhiwo ezingezona kazibuthe, kanye nokugcinwa kalula.Uma ukunemba, ukwethembeka, nokuphila isikhathi eside kubaluleke kakhulu kuhlelo lwakho lokusebenza lokucubungula i-wafer, i-granite ifanele ukucatshangelwa.

Isikhathi sokuthumela: Nov-07-2023